Welcome to the website of the Bargatin group at the University of Pennsylvania!

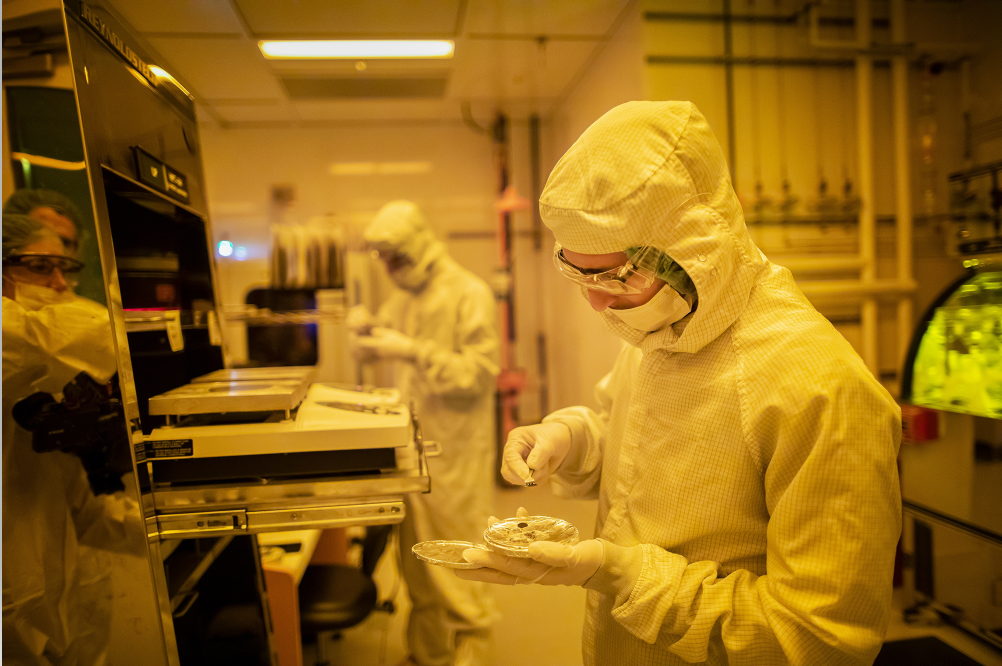

We push the limits of nanofabrication techniques to create materials and structures with unprecedented mechanical properties and to enable applications such as heat-to-electricity direct energy conversion, new levitation techniques for microflyers, and interstellar travel using a lightsail (also known as project Starshot).

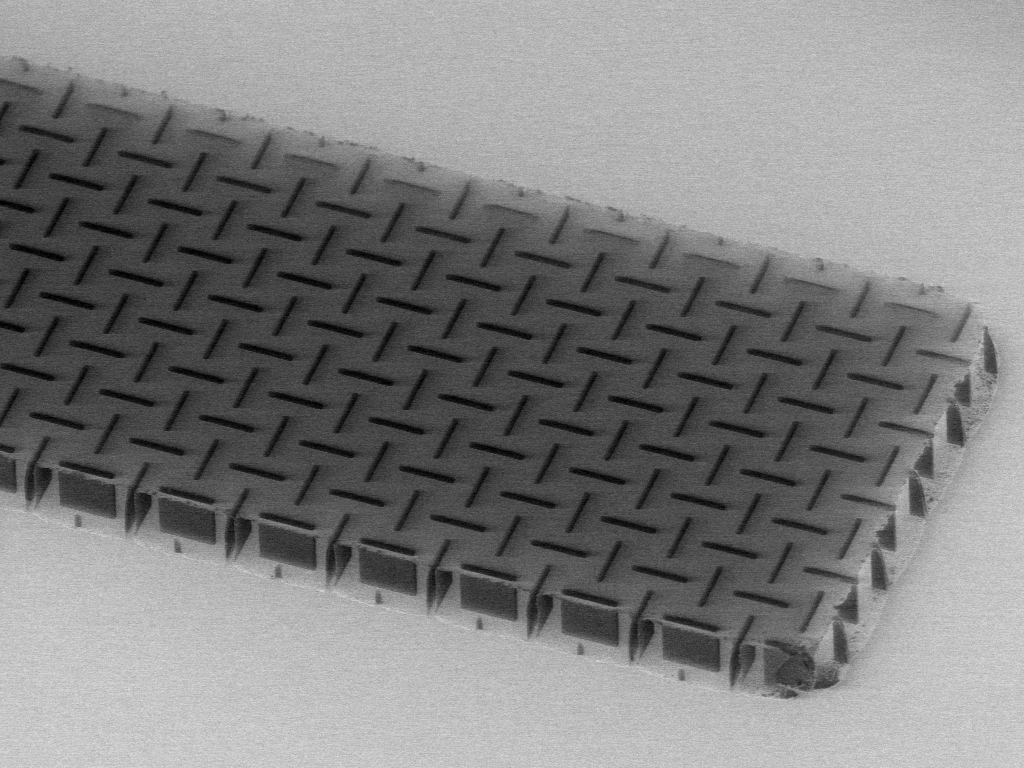

We recently invented plate mechanical metamaterials, creating the thinnest plates that can be picked up by hand as well as nanocardboard – the nanoscale analog of corrugated cardboard and other sandwich composite plates. We design and test new types of energy devices, such as microfabricated thermionic energy converters, which convert heat directly to electricity at very high temperatures by literally boiling electrons off a surface and using them as a “working fluid” in a heat engine. Finally, we are studying new methods of levitation and propulsion without moving parts.

Our group is very interdisciplinary, engaged in research at the intersections of mechanical engineering, electrical engineering, materials science, and applied physics. We believe that our research is better with a diverse team. We embrace and encourage our lab members’ differences in age, color, disability, ethnicity, family or marital status, gender identity or expression, language, national origin, ability, political affiliation, race, religion, sexual orientation, socio-economic status, veteran status, and other characteristics that make our lab members who they are.

We are currently looking for new PhD students and/or postdocs to join the group! If you are interested, please email your CV and unofficial transcript to Prof. Bargatin.